Feeding size: 0.15-2mm

Feeding amount: 10-60t/d

Processing Material: tin ore, tungsten, gold and silver ores, lead, zinc, tantalum, niobium ore, iron, manganese, titanium, and coal, etc.

40 Years history production base and exporter

Pre-sale service

Pre-sale service

24 hours online

Free technical support and solutions

Factory visit anytime, free pick up

Sales service

Sales service

Commit to delivery fast

Provide On-site installation service

Free training of product operation

After-sales service

After-sales service

365 days after-sales online

Solve customer feedback problems timely.

Help customers optimize and upgrade equipment

Contact Us ( sales@sinofote.com )

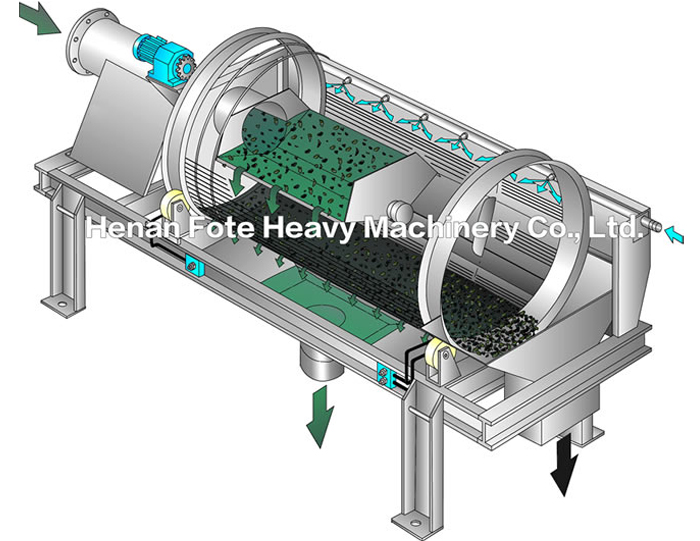

Rotary trommel screen consists of five parts as drum, frame, hopper, reducer and motor.

1)Gold Mine: gold screening and washing

2)Quarry: gravel, clay, mountain meal, sand, etc.

3)Coal Industry: lump coal, coal dust, coal washing, etc.

4) Chemical Industry: sifting calcium oxide, compost

5) Metallurgy, construction, mineral-selecting, etc.

1.Economical and efficient solution for screening;

2.Heavy duty trommel drum with lifters at the front to facilitate material break up;

3.Screen replaceable for different mesh sizes; 4. Easily change screen plates;

5. High efficiency and big capacity;

6. Heavy duty feed hopper;Discharge chute;Gear drive mechanism.

7. Unique screen design, result in higher capacities, longer screen life and no material clogging;

1) Input of raw materials through heavy equipment

Raw materials inputted through the entrance of the hopper will be pushed into the trommel screen by the strong water pressure of the shower equipped in the hopper.

2) Selection and cleaning of raw materials Raw materials of the trommel screen will be cleaned and selected by the rotation of trommel screen and, by watering of the shower inside, run into the gold dust separate panel.

3) Collecting of gold dust separated Soil and sands with lighter specific gravity will flow away but gold dusts with greater specific gravity will be staying in the gathering mat to be collected.

| Model | Capacity (t/h) | Power (kw) |

|

| Sieve hole(2mm) | Sieve hole(30mm) | ||

| YTS1230 | 4-12 | 16-50 | 5.5 |

| YTS1240 | 4.5-14 | 20-60 | 5.5 |

| YTS1250 | 5-15 | 23-70 | 5.5 |

| YTS1530 | 6-18 | 25-75 | 5.5 |

| YTS1540 | 6-18 | 25-75 | 7.5 |

| YTS1550 | 7-20 | 26-80 | 11 |

| YTS1560 | 7-22 | 33-100 | 11 |

| YTS2040 | 8-25 | 40-120 | 11 |

| YTS2050 | 10-30 | 50-150 | 11 |

| YTS2060 | 12-35 | 55-175 | 11 |

| Model | Capacity (t/h) | Power (kw) |

|

| Sieve hole(2mm) | Sieve hole(30mm) | ||

| YTS1230 | 4-12 | 16-50 | 5.5 |

| YTS1240 | 4.5-14 | 20-60 | 5.5 |

| YTS1250 | 5-15 | 23-70 | 5.5 |

| YTS1530 | 6-18 | 25-75 | 5.5 |

| YTS1540 | 6-18 | 25-75 | 7.5 |

| YTS1550 | 7-20 | 26-80 | 11 |

| YTS1560 | 7-22 | 33-100 | 11 |

| YTS2040 | 8-25 | 40-120 | 11 |

| YTS2050 | 10-30 | 50-150 | 11 |

| YTS2060 | 12-35 | 55-175 | 11 |

Through long-term arduous technology research and international communication, our product quality has been in line with international level, winning a world-wide acclaim and honor, and our products are exported to ninety countries and regions like Tanzania, Nigeria, South Africa, Kenya, Turkey, Saudi Arabia, Philippines, Indonesia, Malaysia, Vietnam, Mexico, Brazil, Russia, Uzbekistan, Australia, etc.

Please feel free to write down your requirement in the form below.

We will reply you within 24 hours.

Copyright: China Henan Fote Mining Machinery Co., Ltd.All rights reserved